Los Angeles Cool Roof Coatings

Los Angeles, CA: Commercial cool roof restoration (aka commercial cool roof coatings) can be a smart alternative to a tear-off provided the flat or low-slope roof is a good candidate. When Los Angeles & Orange County needs a commercial cool roof coating they call the commercial roofing contractors here at Central Roofing Company!

During the complimentary estimate, Central Roofing Company will determine if your existing roof is a prime candidate for a roof coating application.

Not only that. Being that there are two coating materials that are used for the commercial roof systems. Acrylic and Silicone Coatings. Both commercial cool roof coatings meet Title-24 compliance. BUT there are pros and cons for both cool roof coatings that you’ll have to consider before deciding. Our flat roofing experts will rundown the pros and cons for both along with our best recommendation.

Orange County Cool Roof Coatings

Although we are headquartered in Gardena, Los Angeles, we have offices spread throughout the region including Orange County. Orange County commercial property managers, building owners, and facilities managers rely on Central Roofing to get their roofing projects done right and on budget. Our team is experienced in all the different types of commercial roofing membranes. Including TPO, PVC, Modified Bitumen, and Built-Up Roofing Systems. FREE OF CHARGE our team of experts will evaluate your roofing system and determine which cool roof coating is the right fit for your building.

F.A.Q Commercial Roofing

What Areas Do You Serve?

We serve Los Angeles, Orange, and San Bernardino Counties

What Type Of Warranties Do You Offer?

Our Warranties can vary depending on the roofing materials used and the manufacturer. However, at Central Roofing our commercial roofing warranties offer YOU coverage for up to 30 years!

Are You Fully Licensed And Insured?

Yes we are fully insured and licensed. Our insurance covers medical expenses and lost wages for workers injured on the job. Hiring a contractor with workers' compensation insurance protects you from being held financially responsible for any injuries that occur on your property.

Liability Insurance: This insurance protects you from any damage that might occur to your property during the roofing project. It ensures that any accidental damage caused by our company is covered, giving you peace of mind that you won't incur unexpected costs.

How Much Does Commercial Roofing Cost?

Pricing depends on a variable of factors, including, labor, materials and location.

What are the different types of commercial roofs?

Metal Roofing.

Built-Up Roofing (BUR) Membrane.

Silicone Coatings.

Acrylic Coatings.

Thermoset EPDM Roof Membrane.

Is a Commercial Cool Roof Expensive?

Costs will vary greatly depending on location and local circumstances.

How effective is cool roof?

Depending on the choice of material, cool roofs can help lower indoor temperatures by 2-5 degree centigrade, offering simple yet effective protection from extreme heat.

How Do I Apply For Cool Roof Rebate?

To see if you qualify, instructions on how to apply, and also see what cool roof rebates are available you may go here.

Re-Roof vs Roof Replacement

Existing roofs with only minor damage or leaks and only have a single layer of roofing are excellent candidates for re-roofing.

On the other hand, if your roof has significant water damage, leaks everywhere, and smells of mold then a roof replacement is the best option.

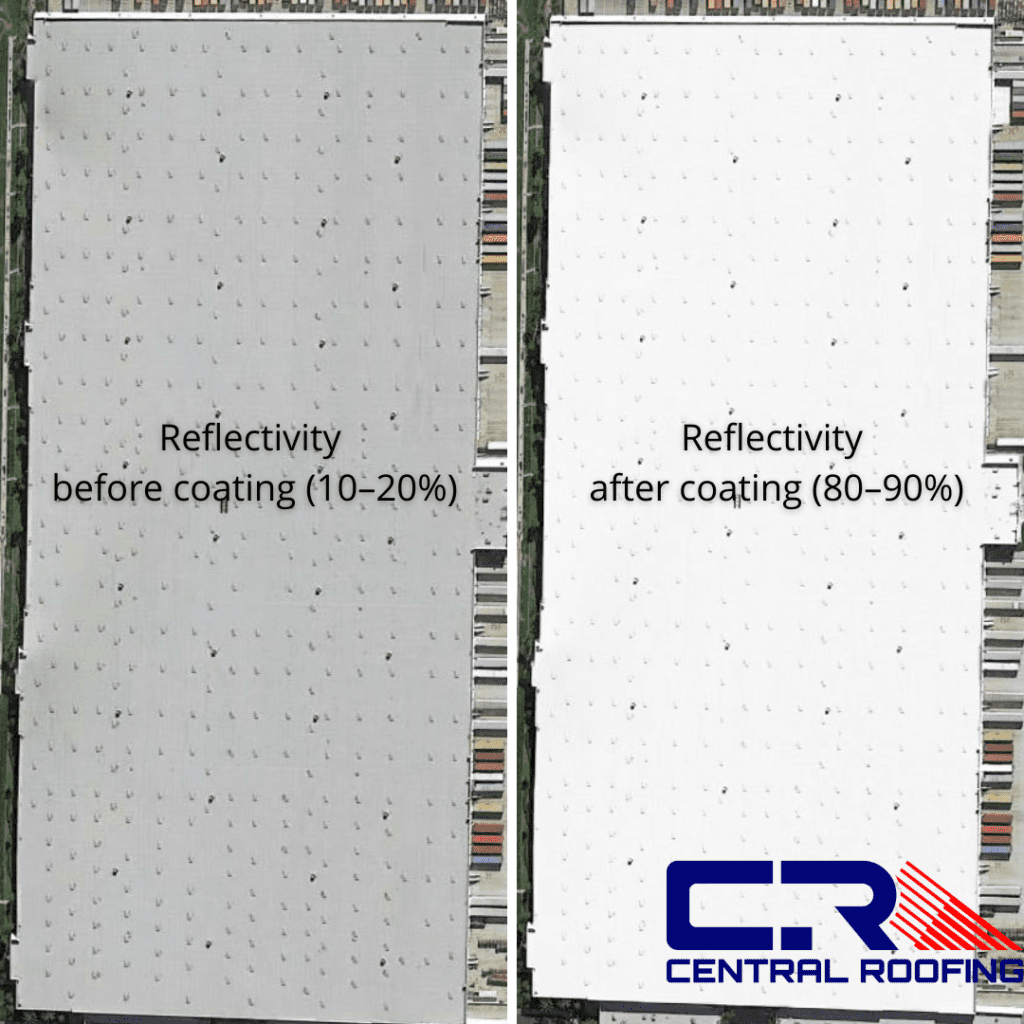

Before vs. After a Commercial Roof Restoration

Mattel contracted with us for an industrial roof project in October 2005. This 172,800 square foot roof restoration was completed in 31 crew days.

The Cool Roof Coating Restoration Process

Roof Preparation

Not to be overlooked, roof preparation is the correction of roof issues prior to installation of the new coating system. This is a critical step to insure a quality installation that will maximize the useful life of the new roof.

Job walk with Central Roofing, Customers to discuss logistics of installation and safety.

Remove dirt, leaves, loose gravel at base flashing of parapet walls, foreign matters, debris, etc. from drains and waterways on an as needed basis.

FIELD: Inspect field membrane for fractures, loose seams or blisters and repair with modified bitumen roof membrane, white flashing grade or microfibers and silicone as required.

PONDING: Supply and install modified bitumen roof membrane at severe ponding areas as required.

PIPES AND VENTS: Seal pipes and vents with flashing grade or microfibers and silicone as required.

Apply Emulsion & Polyester Reinforcement

The combination of applying layers of asphalt emulsion and polyester reinforcement forms a new, seamless, water-proof membrane over the existing roof and areas reinforced by Modified Bitumen.

COPING METAL: Resecure loose coping metal and refasten joints on an as need basis. Reseal joints with white flashing grade or microfibers and silicone as required.

HVAC/MECHNICAL EQUIPMENT/SKYLIGHT CURBS: Reseal A/C curbs with modified bitumen roofing membrane, flashing grade or microfibers and silicone as required.

PRESSURE WASHING: Pressure wash repair area prior to silicone topcoat application.

Apply White Elastomeric Top Coat

After 1 or 2 days of curing, the roof is ready for the white elastomeric top coat to be spray applied directly to the polyester reinforcement. After curing, you have an Energy-Star rated, Title-24 compliant Cool Roof that can dramatically reduce surface temperature and help reduce cooling costs.

Apply one coat of TROPICAL #918B PRIMER at the rate of approximately 1.0 - 1.5 gallons per 100 sq.ft. over entire roof surface.

Detail around roof structures.

Modified Bitumen is a blend of atactic polypylene polymers mixed with high grade asphalt, reinforced with a non-woven polyester mat. The expected useful life of this material is 20 years. Modified Bitumen is the replacement technology for the old Mineral Capsheet (Hot Mop) technology.

13 Reasons to Get a Cool Roof

Applying a white elastomeric topcoat (aka Commercial Cool Roof Coating) to your roof building has numerous advantages over a conventional roof. Roof restoration coating systems comprise approximately 65% of today’s commercial roofing needs. They are more cost-effective than traditional means of re-roofing. And to mention the potential savings in energy bills.

Here are 13 reasons why getting a cool roof makes sense beyond the obvious energy and cost savings:

- 1Minimal inconvenience as there is no need to tear-off existing roofing membrane.

- 2Eliminates need to replace insulation which would be costly.

- 3Lightweight. Additional layers may be added at a future date which can extend the useful life.

- 4Water-based, non-flammable, and odorless.

- 5Seamless, encapsulating the existing roofing membrane.

- 6Superior water proofing qualities.

- 7Extremely flexible with strong elongation properties.

- 8Polyester mat(s) provides superior tensile strength.

- 9Maintains your current fire rating.

- 10Emulsified asphalt deteriorates at a slower rate than hot asphalt-based roof systems.

- 11Materials are environmentally friendly with very low VOCs.

- 12Energy Efficient and Title-24 Compliant. Research has shown a substantial savings.

- 13Potential tax benefits.

Manufacturer Affiliations

Central Roofing Company is proudly affiliated with these manufacturers of commercial roof products designed to surpass industry standards. We determine what product to use based on your particular needs. Each product comes with a manufacturer warranty.

Cool White Elastomeric Roof Coatings:

- APOC

- Tropical

Asphalt Shingle or Composition Shingle:

- Malarkey

- Owens Corning

- Tamko

- Certainteed

- GAF

Torch Modified or Modified Bitumen:

- Polyglass

The Cool Coatings Solution For All Roof Types

One of the best benefits of having a heat-reflective coating is that it can be applied to pretty much any conventional roof system. Including metal roofs, single-ply membranes, modified bitumen, and more.

Cool Roof Coatings can improve your building’s energy efficiency: Cool roof coatings are designed to reflect sunlight and reduce heat absorption, effectively lowering the surface temperature of the roof. By reducing heat transfer into the building, cool roof coatings can significantly improve energy efficiency and reduce energy bills, especially in warmer climates. In short, a cool roof can lead to substantial energy savings over time.

That’s right because protective coatings are liquid based which makes them adaptable to many types of roofing systems. The key to any roofing system is installing it correctly. The commercial roofing professionals at Central Roofing have over 30 years of experience and specialize in energy-efficient roofing systems. Check out our reviews on what some of our clients had to say about us.

Cool roof coatings can be applied to various flat roofing materials, including bitumen, metal, concrete, and modified bitumen. They are compatible with existing roofs, allowing for retrofitting without the need for a full roof replacement. Cool roof coatings can be formulated as liquids or membranes, offering flexibility in application methods and ensuring compatibility with different roof types.

Additionally, they shield the roof from harmful ultraviolet (UV) radiation, which can cause degradation of roofing materials. As a result, cool roof coatings can extend the lifespan of commercial flat roofs and reduce the need for frequent repairs or replacements.

The Cool Roof Eco-Friendly Option

Cool roof coatings can help the environment in several ways:

1. Energy savings: Cool roof coatings are designed to reflect a significant portion of the sun’s heat, reducing the amount of heat transferred into the building. As a result, buildings with cool roofs require less energy for cooling, especially during hot days. By reducing the need for air conditioning, cool roofs help lower electricity consumption, which in turn reduces greenhouse gas emissions associated with power generation.

2. Reduced urban heat island effect: The urban heat island effect occurs when cities and urban areas become significantly hotter than their surrounding rural areas due to the abundance of concrete, asphalt, and other heat-absorbing surfaces. Cool roof coatings help mitigate this effect by reflecting solar radiation and reducing surface temperatures. This can lead to cooler microclimates, improving comfort levels and air quality in urban areas.

3. Decreased air pollution and greenhouse gas emissions: By reducing energy consumption for cooling, cool roof coatings indirectly contribute to reducing air pollutants and greenhouse gas emissions. Power generation from fossil fuels is a significant source of air pollution and carbon dioxide emissions. When buildings consume less energy, power plants can operate at lower capacities or use cleaner energy sources, resulting in fewer emissions.

4. Enhanced roof durability: Cool roof coatings can extend the lifespan of roofs by reducing the amount of thermal stress they endure. By reflecting sunlight and reducing heat absorption, cool roofs experience less expansion and contraction, which can cause roof materials to degrade over time. Prolonging the life of roofs reduces the need for premature roof replacements and decreases waste from discarded roofing materials.

5. Water conservation: Some cool roof coatings have the ability to retain and release water slowly, helping to reduce stormwater runoff. This can alleviate stress on stormwater systems, prevent water pollution, and contribute to water conservation efforts.

It’s important to note that while cool roof coatings offer environmental benefits, their effectiveness can vary depending on factors such as climate, building design, and local conditions. Additionally, cool roofs are more effective in warmer climates compared to cooler regions where heating needs may outweigh cooling requirements. Therefore, it’s essential to consider local climate and building characteristics when evaluating the potential environmental benefits of cool roof coatings.

Client Testimonials

Schedule Free Estimate

Central Roofing Company Headquarters

555 W. 182nd Street

Gardena, CA 90248

310-527-6770

Get A Quote

One of our roofing estimators will gladly meet you to discuss your options and follow up with a free, no-obligation, written estimate.

At Central Roofing Company, we understand that a sturdy and reliable roof is crucial for the success and safety of your commercial property. Our team of highly skilled and trained roofing professionals is committed to delivering exceptional craftsmanship and superior service in every project we undertake.

555 W. 182nd St. Gardena, CA 90248

Ph: 310-527-6770

Our Office Locations:

Our Services

CA license #684960 – Central Roofing, 2024 ©All Rights Reserved | Terms of Use | Privacy Policy | Built by Dymic