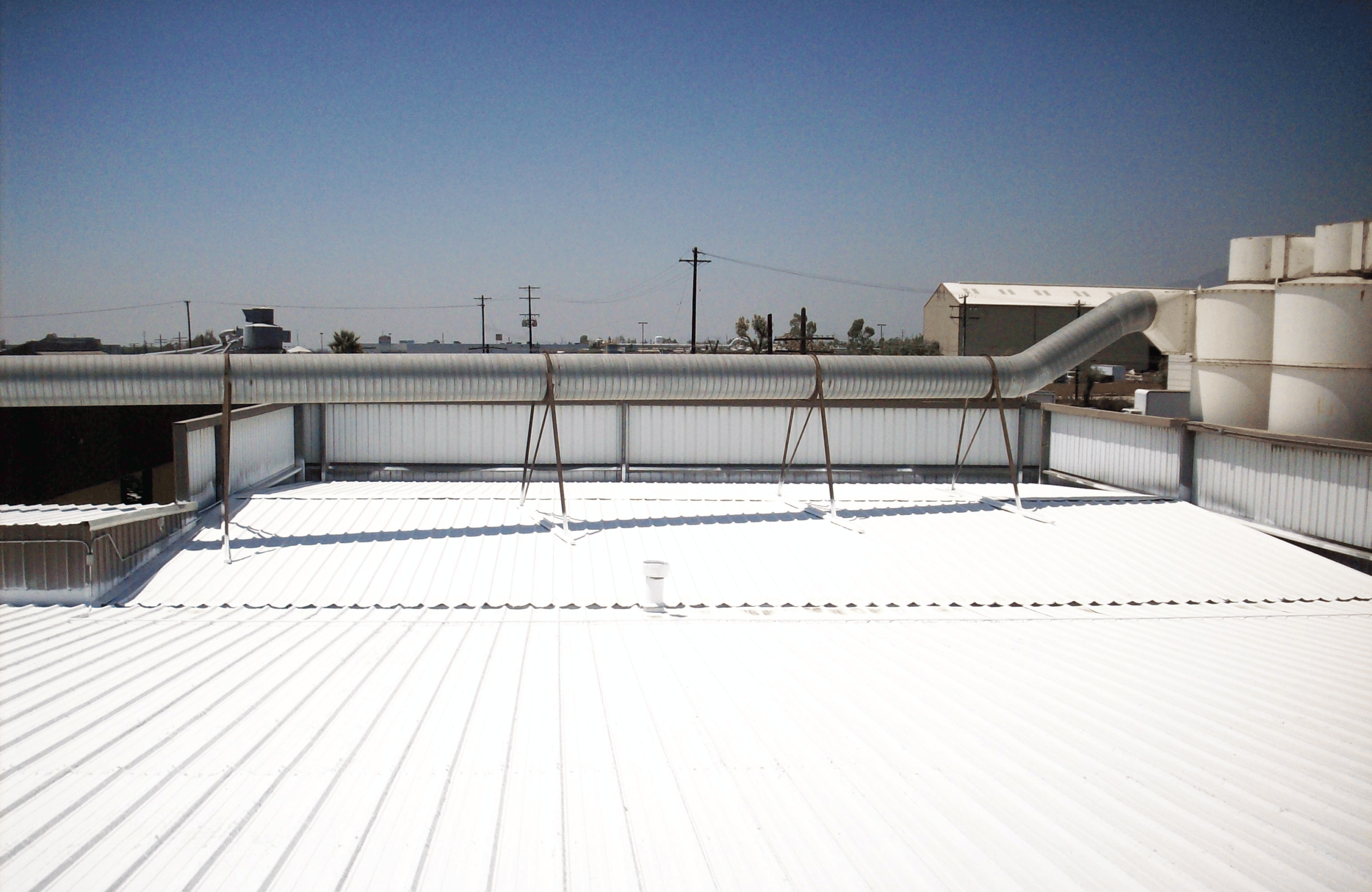

Los Angeles Metal Roof Coatings

At our commercial roofing company, we specialize in providing exceptional metal roof coatings for commercial buildings. Metal roof coatings are an effective and cost-efficient solution to enhance the durability, longevity, and energy efficiency of existing metal roofs. Our skilled team of roofing professionals follows a systematic approach to ensure a high-quality application and optimal performance of the coating.

Over 30 Years of Experience

Our Work is Backed By Our Warranties

Licensed, Insured, And Bonded

Orange County Metal Roof Coatings

Not in Los Angeles? No problem! We have offices in Orange County and San Bernardino County, to help serve your metal roofing needs where you’re at.

What type of buildings do we service? We are strictly a commercial roofing contractor, this includes warehouse roofing, hospital roofing, church roofing, apartment roofing, and of course commercial roofing. Whether your commercial building in Ontario needs service or your warehouse in La Mirada, to an apartment building in the Inland Empire, you can count on Central Roofing to be there when you need a commercial metal roof coating.

Metal Roof Cool Roof Coating Materials We Use

We offer a comprehensive range of metal roof coatings, including acrylic and silicone coatings. These materials are popular choices due to their exceptional performance, durability, and versatility in protecting and enhancing metal roofs. Here's a description of how we utilize acrylic and silicone materials in our metal roof coating process:

Acrylic Metal Roof Coatings:

Acrylic coatings are water-based and provide a seamless, protective barrier cool roof coating on metal roofs. Here’s how we utilize acrylic materials in our metal roof coating process:

Surface Preparation: We start by preparing the metal roof surface, ensuring it is clean, dry, and free from any contaminants. This step is crucial for promoting optimal adhesion and performance of the acrylic coating.

Primer (if necessary): Depending on the condition of the metal roof, we may apply a primer to enhance adhesion and ensure a strong bond between the surface and the acrylic coating.

Application: Our experienced roofing professionals apply acrylic coating using specialized equipment and techniques. We ensure uniform and even coverage across the entire roof surface, paying close attention to seams, edges, and penetrations.

Curing and Inspections: After the acrylic coating is applied, it undergoes a curing process, forming a protective layer that is resistant to UV rays, weathering, and other environmental factors. We conduct thorough inspections to ensure the coating has adhered to correctly and meets our quality standards.

Performance and Benefits: Acrylic coatings offer several benefits for metal roofs, including excellent waterproofing, UV resistance, and flexibility. They help to prevent leaks, protect against corrosion, and extend the lifespan of the roof. Acrylic coatings also provide energy savings by reflecting sunlight and reducing the heat absorbed by the building, thereby improving its overall energy efficiency.

Silicone Metal Roof Coatings:

Silicone coatings are known for their exceptional durability, weather resistance, and ability to withstand extreme temperatures. Here’s how we utilize silicone materials in our metal roof coating process:

Surface Preparation: Similar to acrylic coatings, we begin by preparing the metal roof surface, ensuring it is clean, dry, and free from contaminants. This step is crucial for promoting optimal adhesion and performance of the silicone coating.

Primer (if necessary): Depending on the specific silicone coating system chosen and the condition of the metal roof, we may apply a primer to enhance adhesion and ensure a strong bond between the surface and the silicone coating.

Application: Our skilled roofing technicians apply silicone coating using specialized equipment and techniques. We ensure a consistent and uniform application, paying attention to details and critical areas of the roof.

Curing and Inspections: After the silicone coating is applied, it undergoes a curing process, forming a durable, waterproof, and flexible layer. We conduct thorough inspections to verify the integrity of the coating and ensure it meets our quality standards.

Performance and Benefits: Silicone coatings offer excellent resistance to UV rays, extreme temperatures, and weathering. They provide superior waterproofing properties and can expand and contract with the metal roof, minimizing the risk of cracks or leaks. Silicone coatings also have exceptional longevity, requiring minimal maintenance over time.

Whether it’s acrylic or silicone, we ensure that the metal roof coatings we apply are of the highest quality, delivering exceptional protection and enhancing the performance of your commercial roof. Our skilled team follows industry best practices and stays up-to-date with the latest advancements in coating technologies to provide you with reliable, long-lasting solutions.

How Our Commercial Metal Roof Coating Process Typically Unfolds:

Consultation and Assessment: Our experienced team begins by conducting a thorough assessment of your commercial metal roof. We evaluate its condition, identify any existing issues or damage, and determine the most suitable coating system for your specific needs. We take into account factors such as roof slope, climate, and the desired level of protection.

Surface Preparation: Proper surface preparation is crucial for ensuring the adhesion and longevity of the metal roof coating. We start by thoroughly cleaning the roof surface, removing any dirt, debris, or loose paint. Next, we inspect the roof for rust or corrosion and address these issues accordingly. We may apply a rust inhibitor or perform necessary repairs to ensure a solid substrate for the coating.

Priming (if required): Depending on the specific coating system chosen and the condition of the metal roof, we may apply a primer to enhance adhesion. The primer creates a strong bond between the metal substrate and the coating, promoting long-lasting protection.

Application of Metal Roof Coating: We use high-quality, industry-approved metal roof coatings that are specifically designed for commercial applications. Our skilled roofing technicians apply the coating using advanced techniques and equipment, ensuring a uniform and even coverage across the entire roof surface. We pay close attention to details such as seams, edges, and penetrations to ensure complete protection.

Curing and Inspections: Once the metal roof coating is applied, it goes through a curing process, allowing it to form a seamless, waterproof barrier. We conduct thorough inspections to verify the integrity of the coating, ensuring it adheres correctly and provides the desired protective properties. This step helps identify any potential issues and allows for timely corrections if needed.

Final Touches: After the metal roof coating has cured, we perform any necessary touch-ups and clean the work area. We take pride in leaving the premises in a clean and orderly condition, respecting your property and minimizing disruptions to your business operations.

Maintenance and Warranty: We provide guidance on post-application maintenance practices to maximize the lifespan and performance of the metal roof coating. Additionally, we offer warranties on our workmanship and the products used, giving you peace of mind and ensuring that you receive long-term value from your investment.

At Central Roofing Company, we prioritize customer satisfaction and strive to deliver exceptional service. Our expertise in commercial metal roof coatings, combined with our commitment to quality and professionalism, allows us to provide reliable solutions that protect and enhance your commercial property.

Manufacturer Affiliations

Central Roofing Company is proudly affiliated with these manufacturers of commercial roof products designed tosurpass industry standards. We determine what product to use based on your particular needs. Each product comes with a manufacturer warranty.

Asphalt Shingle or Composition Shingle:

- Owens Corning

- Certainteed

- GAF

Torch Modified or Modified Bitumen:

- Polyglass

Central Roofing Company

555 W. 182nd Street

Gardena, CA 90744

PH: 310-527-6770

Since the 1980s I've worked with numerous roofing contractors and consistently relied on Central Roofing. The staff is professional, produces quality work, and recommends alternatives when applicable. Main decision... read more point is Central Roofing is one of very few companies who honor their warranty. With two decades of business now, I continue to recommend Central Roofing to other property management firms as well as family members. Their most recent work in July 2023.

September 13, 2023

Let’s Fix Your Roof Right — Get a Free Estimate Today

Serving Los Angeles & Orange County for 30+ years.

Trusted. Local. Professional.

Central Roofing Company Headquarters

555 W. 182nd Street

Gardena, CA 90248

📞 310-527-6770

Get A Quote

One of our roofing estimators will gladly meet you to discuss your options and follow up with a free, no-obligation, written estimate.

At Central Roofing Company, we understand that a sturdy and reliable roof is crucial for the success and safety of your commercial property. Our team of highly skilled and trained roofing professionals is committed to delivering exceptional craftsmanship and superior service in every project we undertake.

555 W. 182nd St. Gardena, CA 90248

Ph: 310-527-6770

Our Office Locations:

Our Services

CA license #684960 – Central Roofing, 2025 ©All Rights Reserved | Terms of Use | Privacy Policy | Built by Dymic