When it comes to your business, your roof is perhaps the most critical yet underappreciated part of your commercial establishment. Facing the elements and every weather condition imaginable, a commercial roofing system is tasked with keeping your business running smoothly by ensuring that the interior of your building is safe, dry, and clean. But eventually, the day will come when you will need to replace or repair your commercial roofing system.

And when that time comes, you’ll likely find yourself bombarded with commercial roofing contractors who are eager to sell you the latest, greatest “new “technology in roofs—they promise that their product will keep you safe and dry, but how do you know which one is best for you? And is it even worth considering alternatives?

We say yes! There are plenty of great options available—but we’d like to tell you about two in particular: Thermoplastic Polyolefin (TPO) Vs. Polyvinyl Chloride (PVC) Commercial Roofing Systems.

These two are the top single-ply commercial roofing systems on the market. Thermoplastic Polyolefin (TPO) and Polyvinyl Chloride (PVC) Commercial Roofing Systems, But Which one is better? Let’s find out!

Let’s start with the basics.

What Is Thermoplastic Polyolefin (TPO)?

When it comes to commercial roofing, there are a lot of options to choose from. But one that’s steadily gaining popularity is thermoplastic polyolefin (TPO). Thermoplastic polyolefin (TPO) is a single-ply roof membrane. It was invented in the 1990s, and since then, it has steadily gained popularity as a roofing option.

TPO is composed of a blend of rubbers and distinct fillers to create three bonded layers: a thermoplastic polyolefin base layer; a polyester-reinforced fabric center, aka “scrim,”; and a thermoplastic polyolefin top layer. This allows TPO to be lightweight yet strong. It also allows it to be flexible enough to withstand wind loads while still providing superior moisture resistance.

It’s not just the durability that makes TPO such a popular choice for commercial roofs—its energy efficiency also contributes to its popularity. Beyond that, though, it’s also aesthetically appealing. Because TPO can mimic many different textures, it can be designed to complement almost any style of architecture.

Overall, TPO, with its seamless design, offers sturdy protection from the elements and is an appealing addition to any commercial establishment.

What Is Polyvinyl Chloride (PVC) Roof?

When you hear “plastic,” the first thing that comes to mind is certainly not “flexible,” but that’s exactly what PVC is. Essentially, it’s a kind of plastic material. It’s made by combining vinyl chloride with other substances and then heated and molded into various shapes, including the ones you can see on the roofs of most buildings around you. The material itself is a synthetic polymer (a thermoplastic polymer). Its main building block is vinyl chloride, but other substances like plasticizers are added during manufacturing as well to provide it with the required flexibility.

Quite impressively, the resulting PVC sheeting has a high tensile strength; that is, it can withstand high amounts of force without breaking or cracking. This unique property makes it a popular choice for use in roofs for both residential and commercial buildings. Buildings that have PVC roofing systems are typically laminated with two sheets of PVC sheeting separated by an air cavity. This air cavity provides insulation against heat loss in winter and summer while also helping to prevent condensation problems.

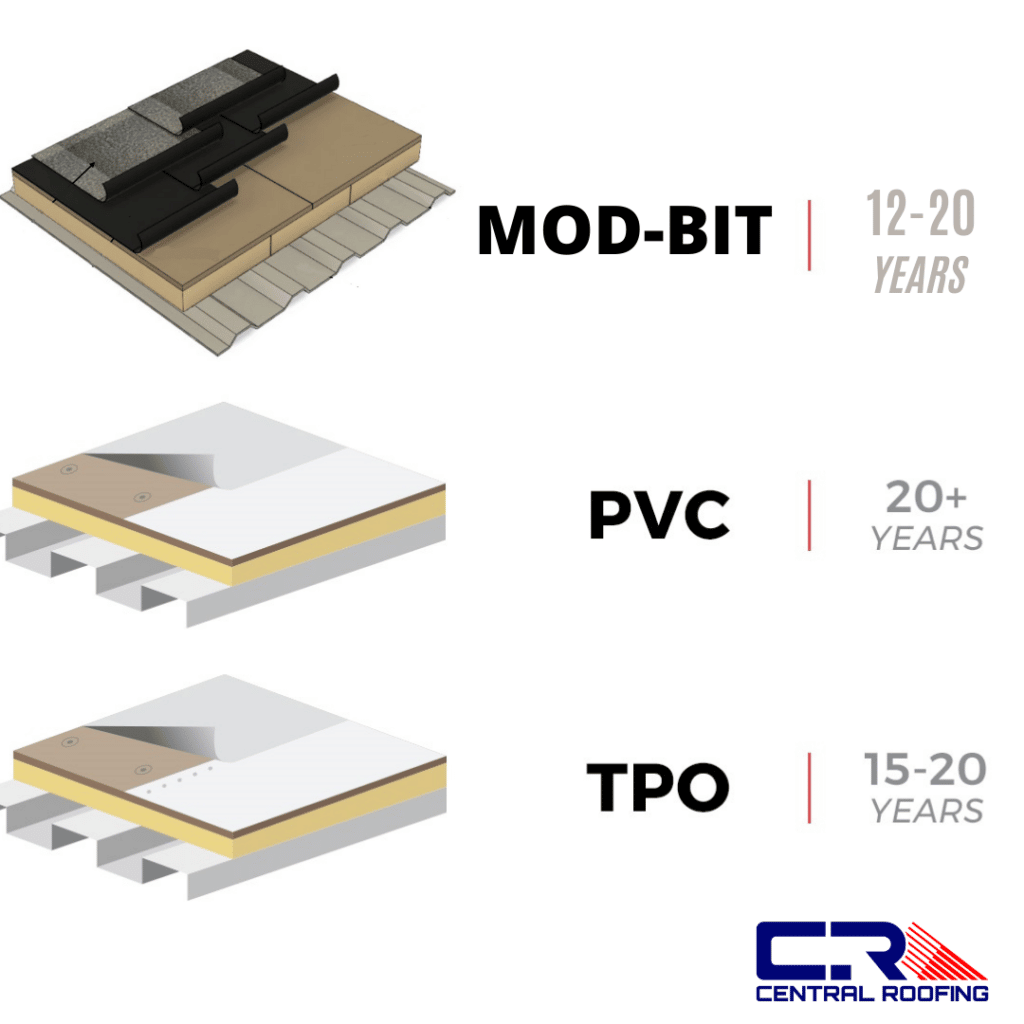

Mod-Bitumen (Multi-Ply) Compared to Single Ply Roofing Systems

Additionally, when correctly installed and maintained, many types of PVC roofing provide waterproof protection as well—a crucial feature for ensuring the longevity of your roof system and your business or commercial establishment from water damage.

Pros and Cons of TPO

Thermoplastic Polyolefin (TPO) is one of the most popular commercial roofing materials in the US today. It is a lightweight, flexible and semi-rigid PVC membrane that offers a wide range of benefits to its users. The material is 100% recyclable and has been tested for high resistance to fire and weathering—making it an excellent choice for commercial roofing applications. In addition, TPO is available in a variety of colors and thicknesses to suit the needs of any project.

The following list contains the most common pros and cons associated with TPO roofing:

Pros:

1. Eco-Friendly

Because TPO is made from petroleum products, it can easily be recycled at the end of its useful life. If you live in an area where recycling programs are available, you can easily dispose of old TPO roofing materials by dropping them off at local recycling centers or transfer stations. When recycled properly, this material will not contaminate our environment or become part of landfills around the world.

2. Durability of TPO Is Unmatched

TPO roofings are heat welded together, which creates a seamless barrier that is impervious to moisture and the elements. In addition, TPO roofing systems are made from polyester fabrics, polypropylene, or fiberglass that are laminated with polymers for added strength. This combination of different materials makes it an extremely durable roofing material.

3. Outstanding Resistance to Ultraviolet

TPO has outstanding resistance to ultraviolet (UV) rays, making it an ideal material for use in areas that experience long periods of direct sunlight. This quality also helps the TPO withstand extreme heat and cold cycles without degradation, which leads to its prolonged lifespan when compared to other types of commercial roofing materials.

4. Energy Efficiency

A major advantage of TPO roofs is their energy efficiency. This material reflects sunlight, which helps keep your home cooler in the summer months and lowers your air conditioning costs. In addition, because it repels heat so well, it also helps reduce ice dams and icicle formation in colder climates during wintertime by keeping the roof warmer than traditional commercial roof materials. This reduction in heat conduction helps control energy costs and makes your home more environmentally friendly.

Cons:

1. Less Resistant to Chemicals

TPO roofs are less resistant to the effects of chemicals than other types of commercial roofing materials. For example, TPO is susceptible to damage when exposed to cleaning products with high concentrations of chlorine. Likewise, in areas where chemical plants and refineries dot the landscape, TPO tends to degrade more quickly than other types of roofing material.

2. Often Difficult to Install Due to Its Inherent Stiffness

TPO roofing is often difficult to install due to its inherent stiffness. This can make it challenging for roofers to work with, particularly when trying to conform the material around curves or other obstacles on the roof.

3. Material Is Relatively New

This product has been around only since the 1980s, and manufacturers may use subpar formulations to cut costs or because they don’t yet understand how to make a quality product. This means that there are plenty of choices when purchasing this type of roofing material, but you should be careful about what company you choose to install it on your building because they could use cheap materials that won’t last as long as they should or cause damage to your building.

Pros & Cons of Polyvinyl Chloride (PVC) for Commercial Roofing:

Polyvinyl Chloride (PVC) is a polymer that has been used for decades to make pipes, vinyl siding, and other building materials. It’s also one of the most common types of commercial roofing materials.

Pros:

1. Low Cost

Polyvinyl chloride (PVC) is one of the least expensive options for commercial roofing. PVC sheets and panels can cost as little as $2 per square foot, which is significantly less than most other materials. This can make it an ideal choice for low-budget projects or when you are working with a limited budget.

2. Durable

The durability of PVC makes it an excellent choice for commercial roofs. The material is highly resistant to UV radiation, which means that it will not fade or discolor over time as some other materials may do. In addition, PVC does not rust as easily as metal sheets or panels do, which means that you won’t have to worry about leaks due to corrosion.

3. Strong

One of the main benefits of using PVC for commercial roofing is its strength. PVC does not bend easily and does not absorb moisture either, so it can stand up well against strong winds and heavy rains. This makes it an ideal option if your business is located in a coastal area where hurricanes are common or if you live in an area where frequent storms occur during the spring months. PVC panels are also flexible enough that they can be shaped easily to fit any size or shape of the roof. This makes it easy to install and maintain, so you save time and money over the years that your business is operating.

4. Lightweight and Easy to Install

While PVC roofing can be a bit more expensive than some of the other options on this list, it is still a very cost-effective choice. PVC panels are lightweight and easy to install, so they can be put up quickly and easily in any location. These lightweight panels also make it much easier to move them around your business property if you decide that you want to move things around or expand in the future.

5. Resistant to Chemical Damage

PVC roofing is also resistant to chemical damage, so it can withstand the harsh chemicals that are often used in industrial settings. This means that you won’t have to worry about your roof being damaged by these chemicals over time, which can save you a lot of money in repairs.

Cons:

1. Somewhat Resistant to Punctures or Weathering

While PVC roofing is quite durable, it is not completely punctured or weather-proof. If something sharp were to fall on your roof, it could cause a small hole or tear. Additionally, over time UV rays and extreme weather conditions can break down the material, causing it to become less effective at protecting your business property.

Consideration When Choosing TPO or PVC Roofing for Commercial Establishment

While TPO and PVC are two very different options, there’s one thing they have in common: Both are highly durable! The lifespan of these materials is typically around 20 years, though it can be longer for some. They’re also resistant to chemicals and UV rays from the sun, which might make them seem like an obvious choice for commercial property owners. However, there’s more than just longevity at stake when deciding on a roofing material—because both options have their own strengths and drawbacks. Let’s talk about the distinctive characteristics of PVC and TPO roofing to help decide which one is right for your business:

1. Cost

When choosing between TPO and PVC roofing, the first consideration should be cost. TPO is cheaper than PVC per square foot of material, so if you have a tight budget, it may be worth considering. However, PVC is more durable and has a longer lifespan than TPO. If you think your roof will last ten years or more, then PVC is a better choice. Moreover, the installation of both types of roofing is quite similar despite their different construction materials. But the installation of TPO roofing is often on the higher end when compared to other types of roofing like wood or tile because it has to be installed by professionals who know what they’re doing and have experience with TPO.

2. Durability

TPO is more durable than PVC because it lacks plasticizers that can make it more brittle and prone to cracking over time. It also has a higher resistance to UV radiation, making it less likely to fade or become damaged by the sun. However, PVC is still a very durable material and will last for many years with proper care and maintenance— you just need to be a little more careful with it than you would some other types of roofing.

3. Flexibility

TPO is more flexible than PVC, making it better able to withstand thermal expansion and contraction without cracking or breaking. This makes it ideal for use in areas that experience extreme temperature changes, such as garages or outdoor decks. However, PVC is still a very flexible material and can be used in many applications where flexibility is not as critical. PVC also has a higher melting point (210 degrees Celsius) than TPO, making it ideal for use in areas where there is potential for exposure to high temperatures.

4. Labor

PVC roofs are generally easier to install than TPO roofs. This is due in part to the fact that PVC with added plasticizers is more flexible, allowing for greater ease of handling. TPO materials are also more expensive than PVC, so the initial cost of installation may be greater. The difference in labor costs, however, is generally not significant enough to offset the lower material costs and longer life expectancy associated with PVC roofing. For this reason, PVC roofing materials are generally less costly than TPO roofing materials.

6. Energy Efficiency

Both PVC and TPO roofing materials are considered to be “cool roof” options. By using a title 24 complaint acrylic or silicone roof coating, a PVC or TPO roof can reflect up to 85% of the sun’s energy. This helps keep building temperatures down, which in turn reduces air conditioning costs.

5. Membrane Quality

The quality of the membrane is an important factor when choosing between PVC and TPO roofing materials. While both types of material are excellent options for commercial roofing applications, PVC membranes have a slightly higher melting point and are less likely to warp or buckle. The combined effects of a higher melting point and less warping mean that PVC roofing materials, when maintained properly, are likely to have a longer lifespan than TPO roofing materials. It also means that PVC roofs are less likely to suffer from leaks

Conclusion

PVC and TPO are both excellent choices for commercial flat roofs. They offer energy savings, low maintenance costs, and a long lifespan. Both types of roofing material are also green options because they can be recycled. Making the decision between PVC and TPO comes down to your particular building needs, which may vary based on industry, climate zone, budget, and other factors. However, there is a caveat,

Both TPO and PVC make for a great commercial roofing system when installed correctly. Yes, there are TPO /PVC roofers out there that do it correctly and install great roofs. But there are a LOT that doesn’t. So, the key is finding a qualified, and experienced commercial roofer that can install the commercial roofing system correctly.

With that being said, PVC has been in the market for a lot longer than TPO. I’m going to give the edge to PVC as it will be easier to find a roofer that can install the system correctly.

[simple-author-box]